SmartTouch™

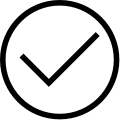

New Shop Floor User InterfaceSmartTouch Interface

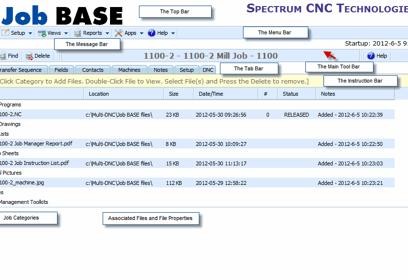

SmartTouch supports both Multi-DNC and Machine Monitoring applications on the shop floor, providing machine operators with easy touch screen or point and click access to DNC files for loading CNC programs and entering a manual parts count which can be emailed to managers. When using monitoring Operators can report part counts, downtime reasons and more.

Customizable buttons make feedback fast and easy

Part Counts

Eliminate the clipboard with electronic parts counts. Final counts are emailed to managers at the end of each shift. Additional features, including alerts are available with Multi-MDC Machine Monitoring.

Operator feedback

Customizable ‘on-touch’ buttons make real-time operator feedback quick and easy. Report problems, downtime reasons and production status information.

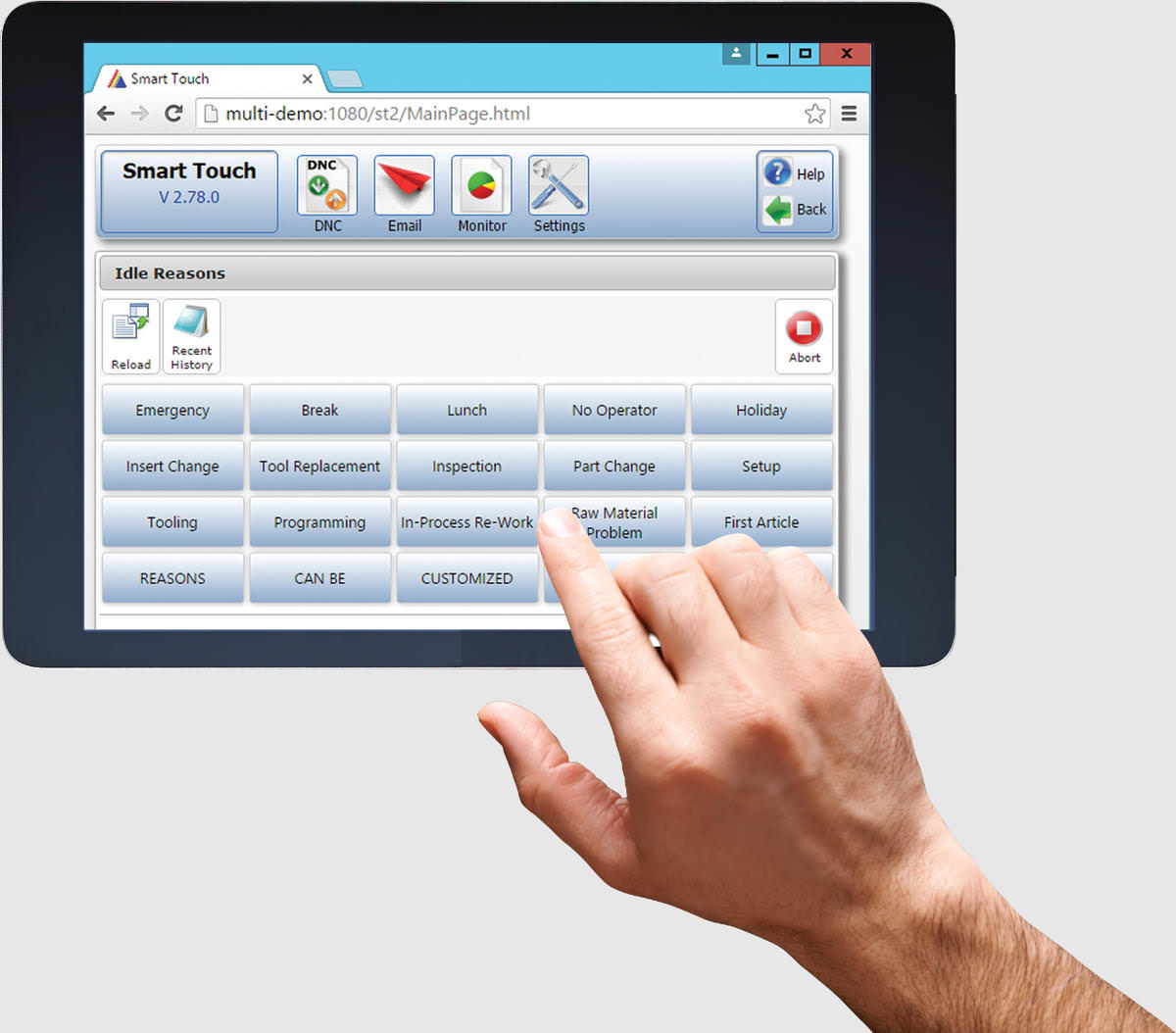

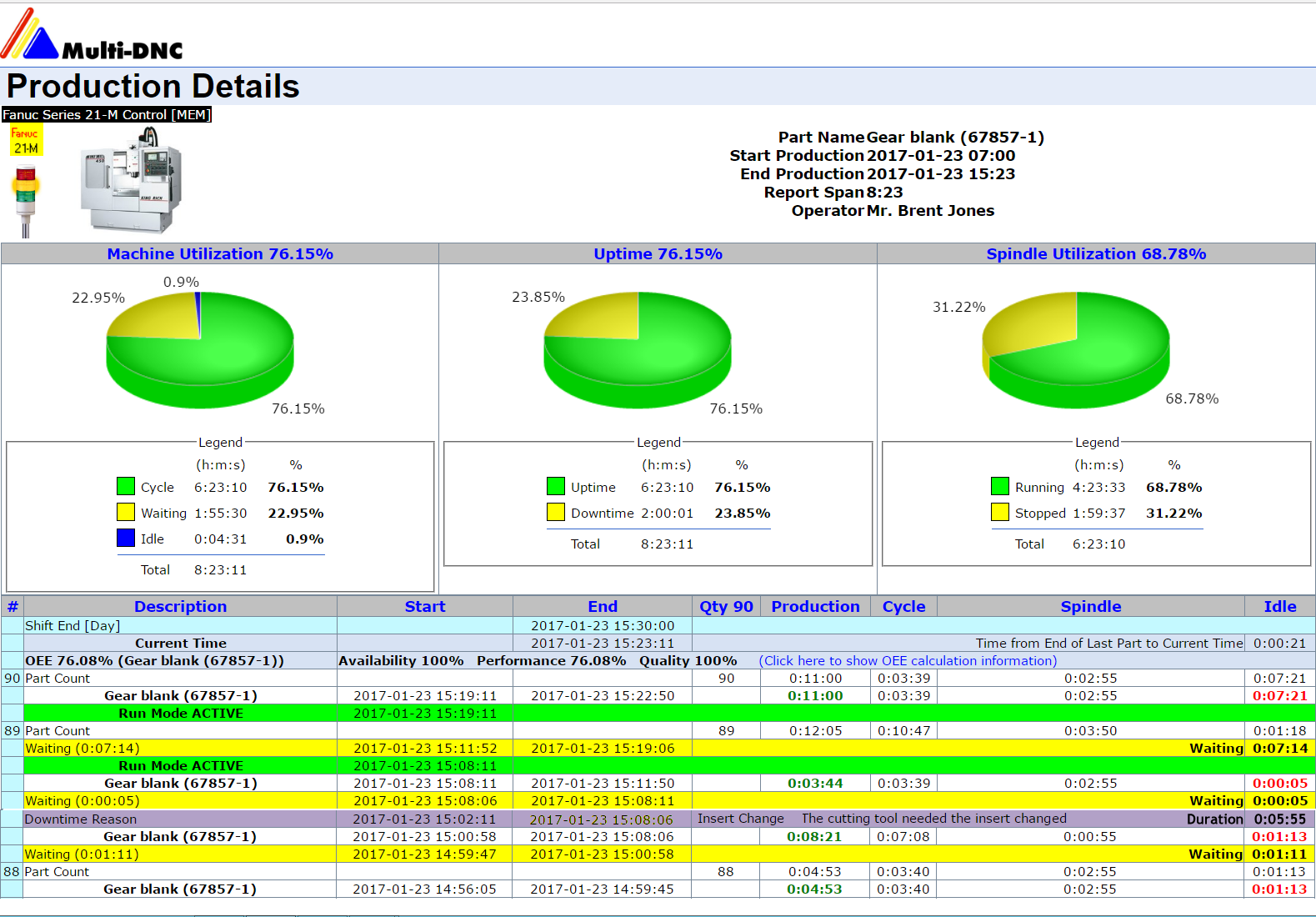

Machine Monitoring

When using SmartTouch with Multi-MDC Machine Monitoring the interface easily toggles between DNC and Monitoring functions, providing a single point of control and feedback.

Reporting and Alerts

Based on user feedback or monitoring triggers, alerts can be automatically sent via email or text. Real-time reports are constantly updated and accessible via browser.

Downtime Reasons

Any number of Idle or Alarm downtime reasons can be created to match your unique shop environment – First Article, Inspection, Break, No Coolant, Tool Replacement, Part Change, Lunch and more.

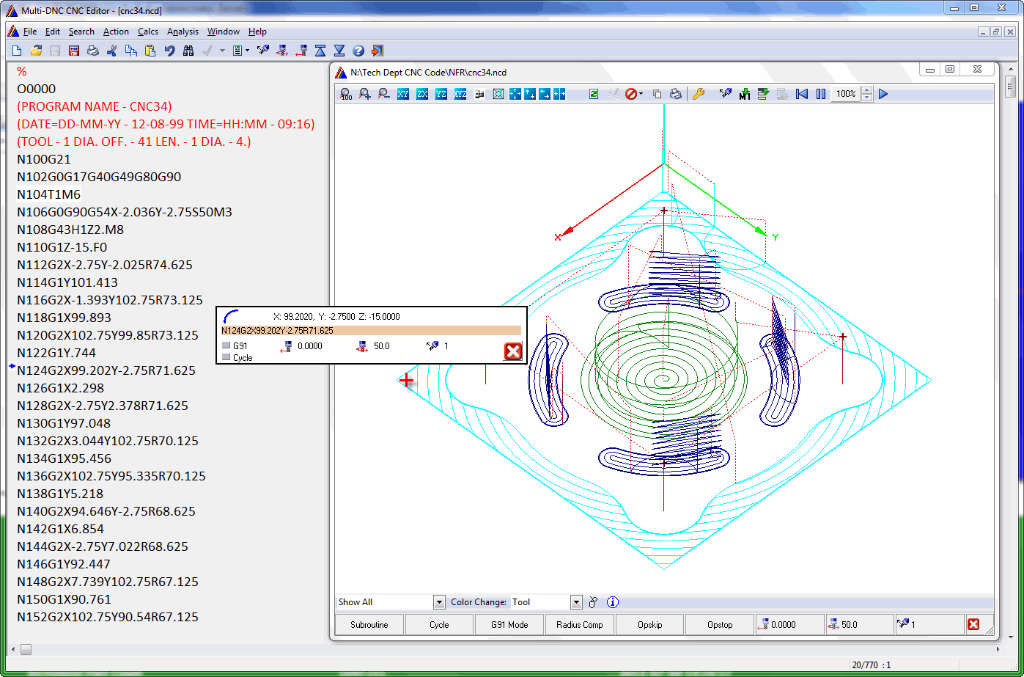

DNC, Machine Communications and Control

Multi-DNC functions available through the SmartTouch interface – Select one or multiple files to Upload-Download or Dripfeed. Operators can also view the send bar as confirmation their files have been sent to the machine tool. They can also load files to multiple machines from a single SmartTouch.

EASY 3-STEP PROCESS

Gets You on Track

Complete Needs Assessment Interview

Review and Approve Solution Quote